Morehouse College Relay Torch

Project Background

Morehouse College is a private, all-male, liberal arts, Historically Black College and University (HBCU) in Atlanta, GA that was established in 1867. In continuing their longstanding educational partnership with the Georgia Institute of Technology, Morehouse commissioned a special commemorative torch that was designed and fabricated by an interdisciplinary team of students from Georgia Tech, with support from Morehouse students.

Relay torches are generally created by dedicated companies over a two year development cycle.

This project made do with four students and a single semester.

Design Goals

Aesthetically reflect the values, personality, and spiritual journey of Morehouse College.

Survive a 150 mile run from Augusta to Atlanta while maintaining the original flame.

Carry and protect an action camera capable of live-streaming content.

Contain a GPS tracker for accurate torch location.

Look at home in the hand of the bearer and/or in a custom stand commemorating the occasion.

Build 5 identical systems.

Aesthetics

The aesthetics for the Morehouse Torch were devised through a combination of imagery on the campus, as well as imagery that represented the traits of the Morehouse Man - the paragon of responsibility, intelligence, and leadership to which all graduates are held. I captured my moodboard by using a mixture of Pinterest inspirations and images I took myself. Full moodboard: https://www.pinterest.com/vgspencer/morehouse-college-torch-aesthetic-inspiration/

Form Development

An Unlikely Inspiration

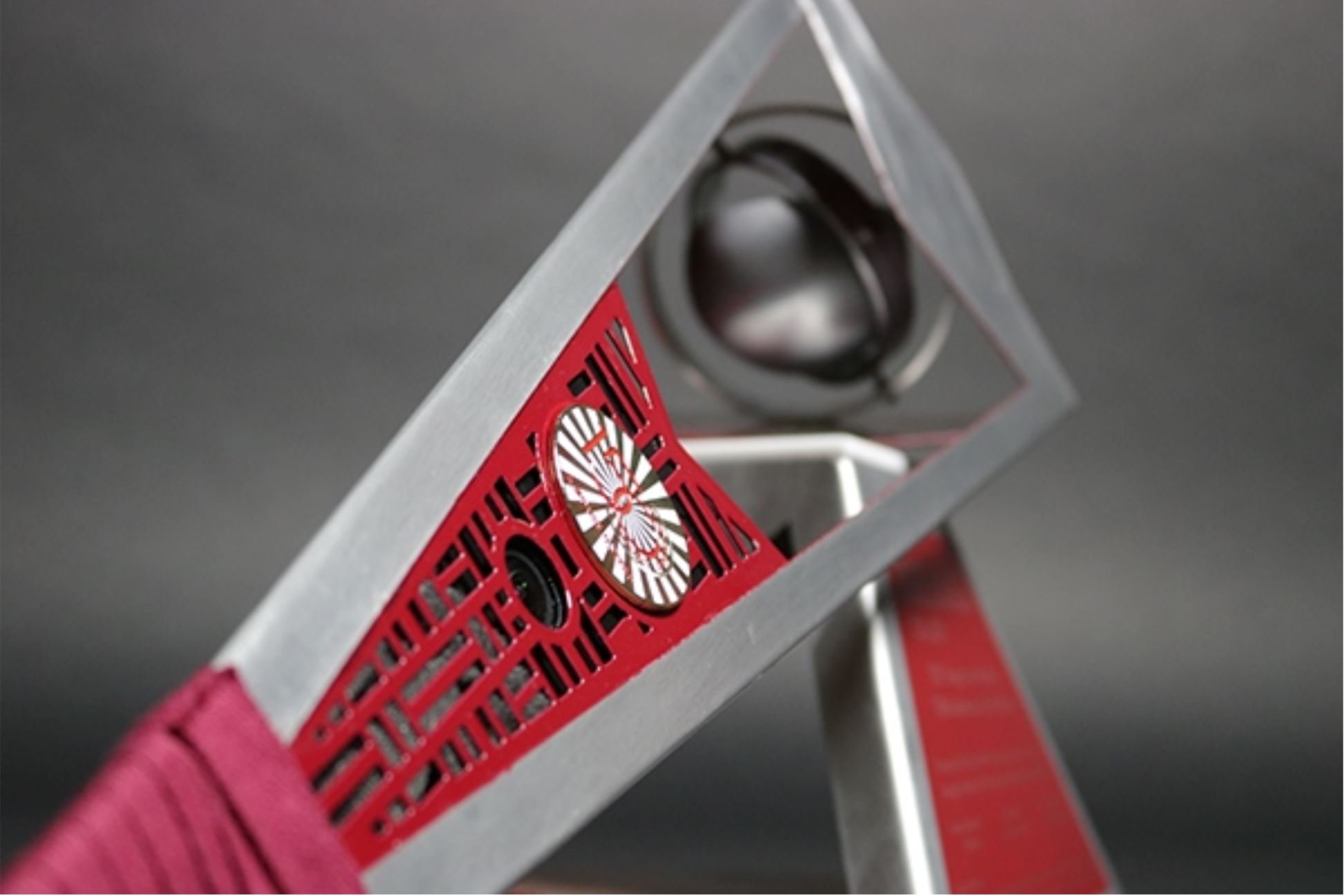

The gyroscope subassembly was used to stabilize the flame and the fuel source during the relay. Because the team lacked the time to develop the liquid-gas most commonly seen in Olympic Torches, the flame was fueled by a gel similar to those found in catering canisters. Based on the popular anti-spill baby bowl design, the gyro successfully contained the fuel source and prevented splashes or other failures.

Final Fabrication

Everyone on the team came together to assist with fabrication. Not only did we construct the torches themselves, we also developed an ecosystem to support the torches for the planned relay logistics.

Parts for the gyroscope assembly were made by the Machining Mall, and the torch bodies were powder coated at Snyder Cycles. We also purchased custom enamel medallions sporting the 150th Anniversary logo. Aside from that, everything was fabricated and tested at the Invention Studio at Georgia Tech, utilizing our waterjet and sheet metal tools.